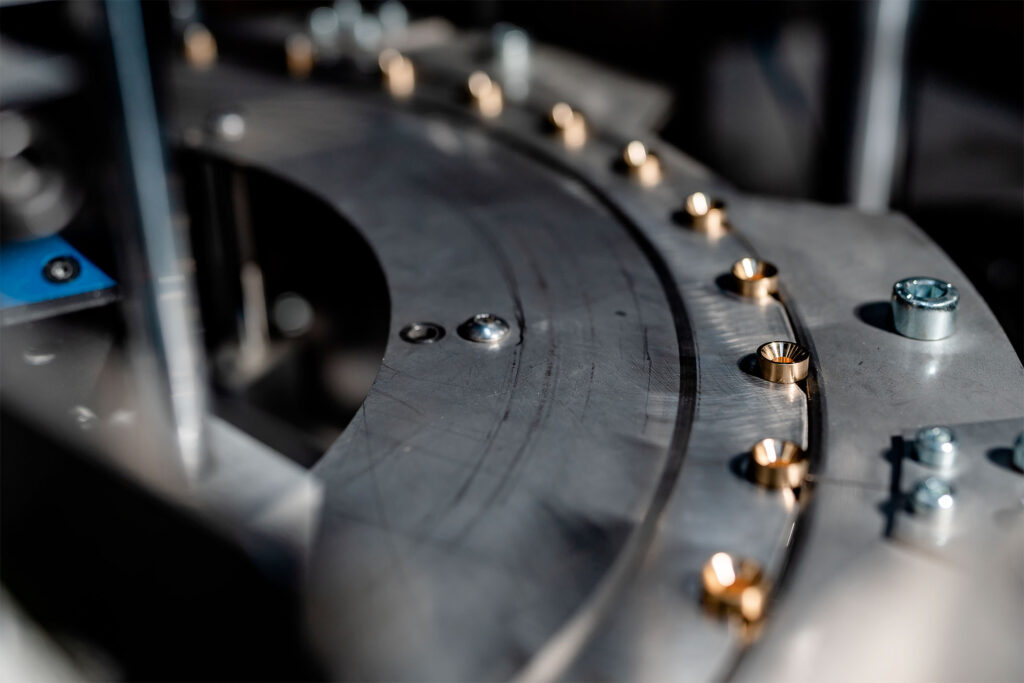

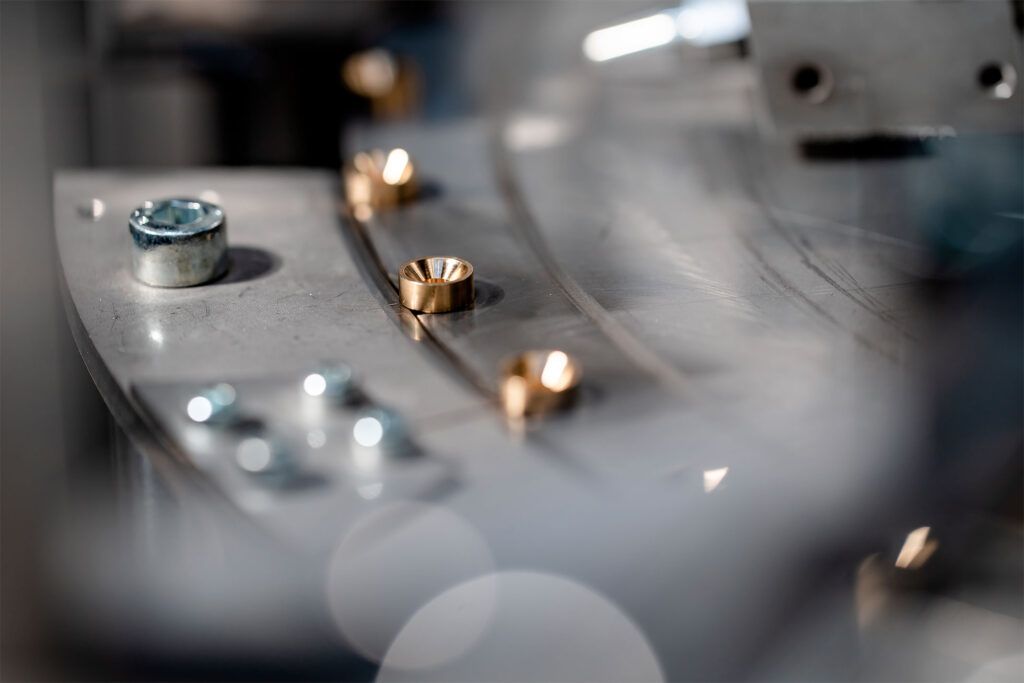

Third-party automatic sorting

Thanks to a large and sophisticated fleet of machines, we perform optical measurements and dimensional checks of parts with guaranteed PPM.

![]()

![]()

![]()

![]()

![]()

![]()

We perform conformity checks on any dimensional parameter requested by the customer with tolerances between 1 and 10 microns.

Checks: Lengths, heights, internal and external diameters, angles

We carry out crack and defect checks by means of:

Bitelecentric and Pericentric optics: optical checks allow us to detect cracks, nicks, dents, burrs with a measurable accuracy in the order of 10 micrometers;

Eddy Current testing devices: these are employed for precise crack and hardness testing, capable of identifying defects as small as a few thousandths of a millimeter, even in hard-to-reach areas.

Slot depth

Presence of blind hole/through hole

Presence of internal and external swarf

Thread check (height, pitch, presence/absence)

Burrs

Accuracy performance down to 2 microns

Metals and plastics also from die-casting or moulding

From 200 pieces to unlimited volumes

Fast service and delivery within one working week

Our automated sorting process is divided into several stages, each designed to optimise quality, speed and accuracy of service.

Send technical drawing with dimensions or defects that require the selection process

Receive feasibility study and customised offer

Send your parts for automatic selection

The parts are automatically selected 100% according to the agreed parameters

Pick up selected parts: those that comply with the warranty stamp, while rejects will be returned separately

Request the sorting report, including a certificate of guarantee and the detected rejection rates

We provide the sorting report with the % of rejection rates resulting from the sorting process