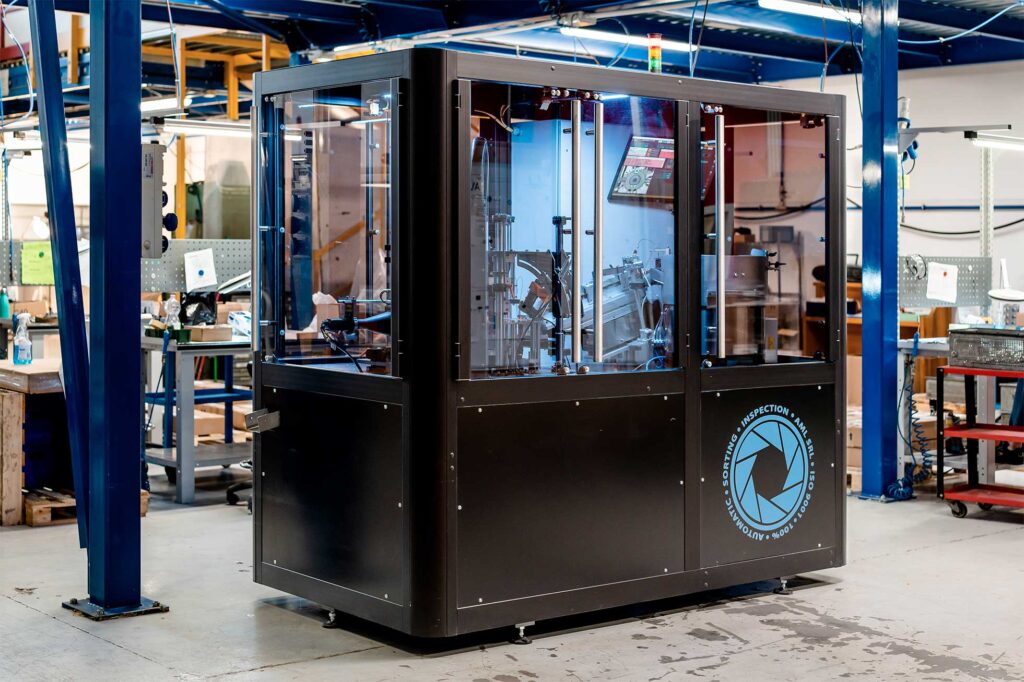

100% inspection and sorting machine with metal disk, designed to detect defects in components with head and shank.

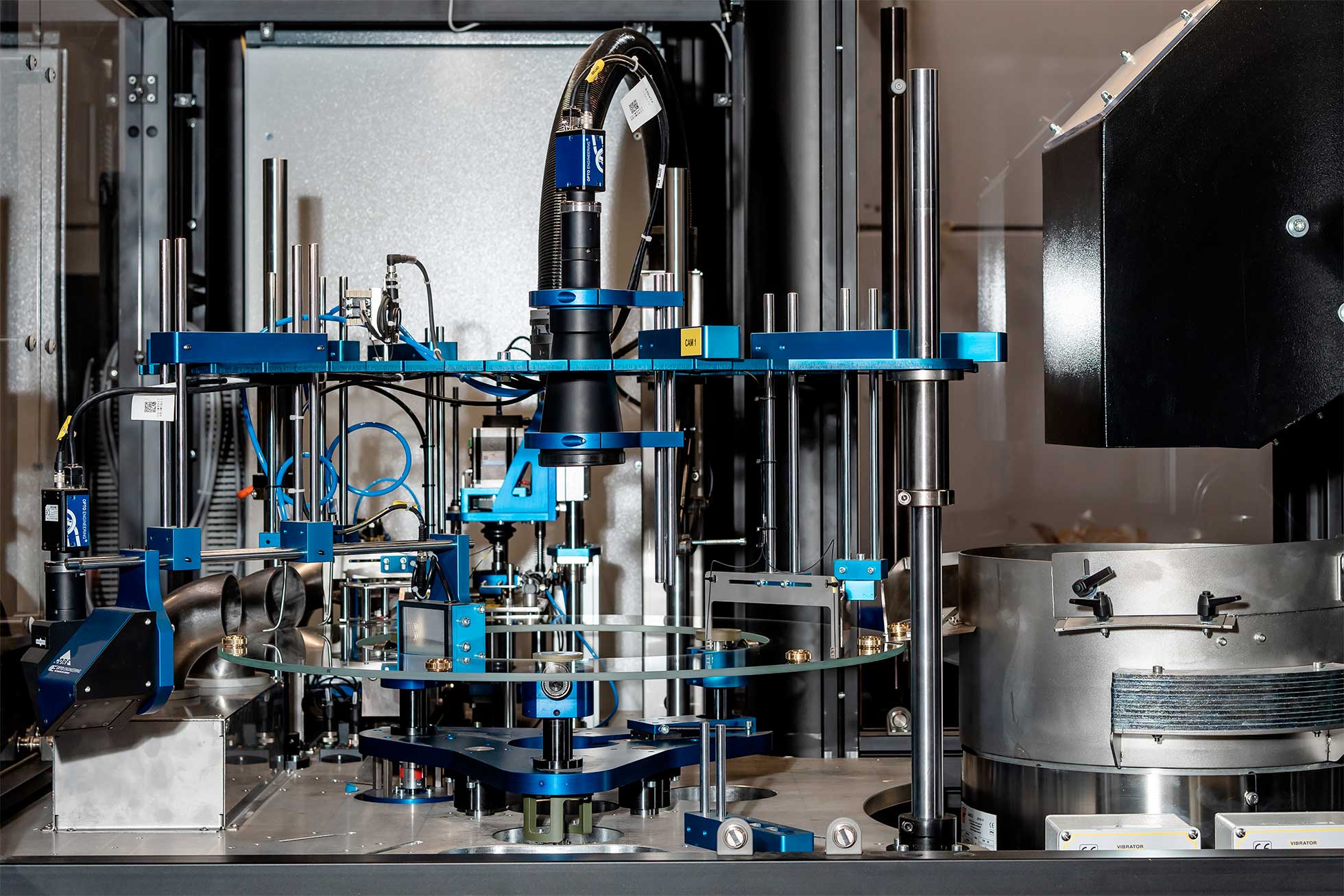

Each machine includes a circular vibratory feeder for loading parts onto a metal disk for hanging components, with multiple inspection stations positioned at various points around the disk (up to 12 stations). Equipped with AML Inspection System vision software and control system. Handling system managed by AML PLC.

Dimensions (lengths, heights, diameters, angles)

Form compliance

Hollow depth

hread control (height, pitch, partial presence, absence)

Each metal disc machine starts from a standard of 3 cameras that can be modified according to customer requirements (up to 12 control stations).

Standard equipment includes:

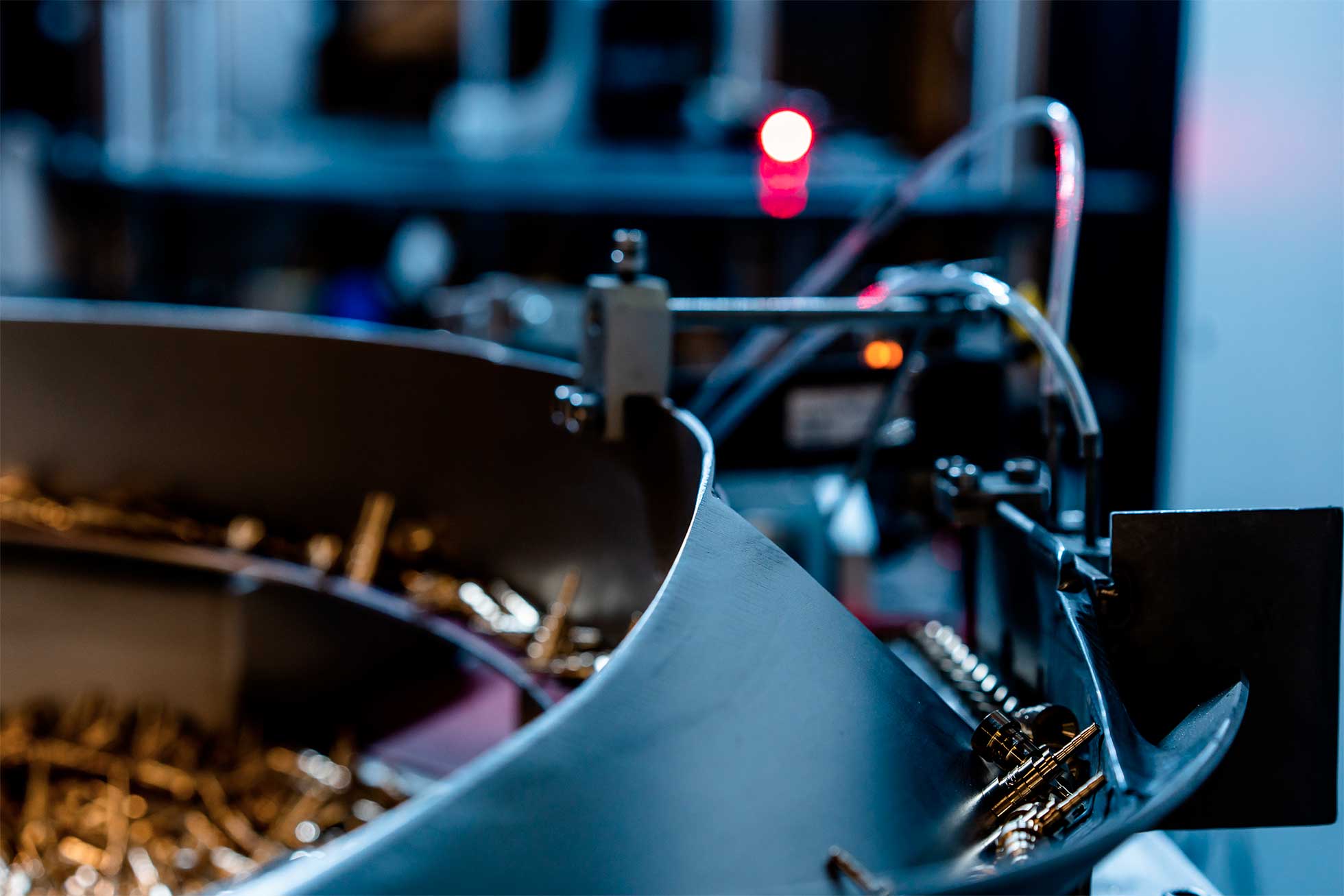

Vibrator for workpiece loading

Metal tables with slots of different sizes (8 included)

3 control stations

ASEM 18.5 ‘Wide Screen’ touch panel with clear and comprehensive multilingual interface for managing settings and custom recipes

Unlimited number of recipes

Selection reports with sorting statistics, measurements and defect reports

Data backup system

Customisable control stations as required (laser micrometer, pass-to-pass gauge, etc.)

Aml machines are designed to adapt to different production requirements. This is why packaging and automatic loading systems and various customised elements can be integrated.

Performed on a station with a horizontal camera equipped with telecentric optics and illuminator, using electric axes managed by recipe based on the selected mode:

1- Lifting of the part

2- Part rotation on the table via magnet

3- Insert height check