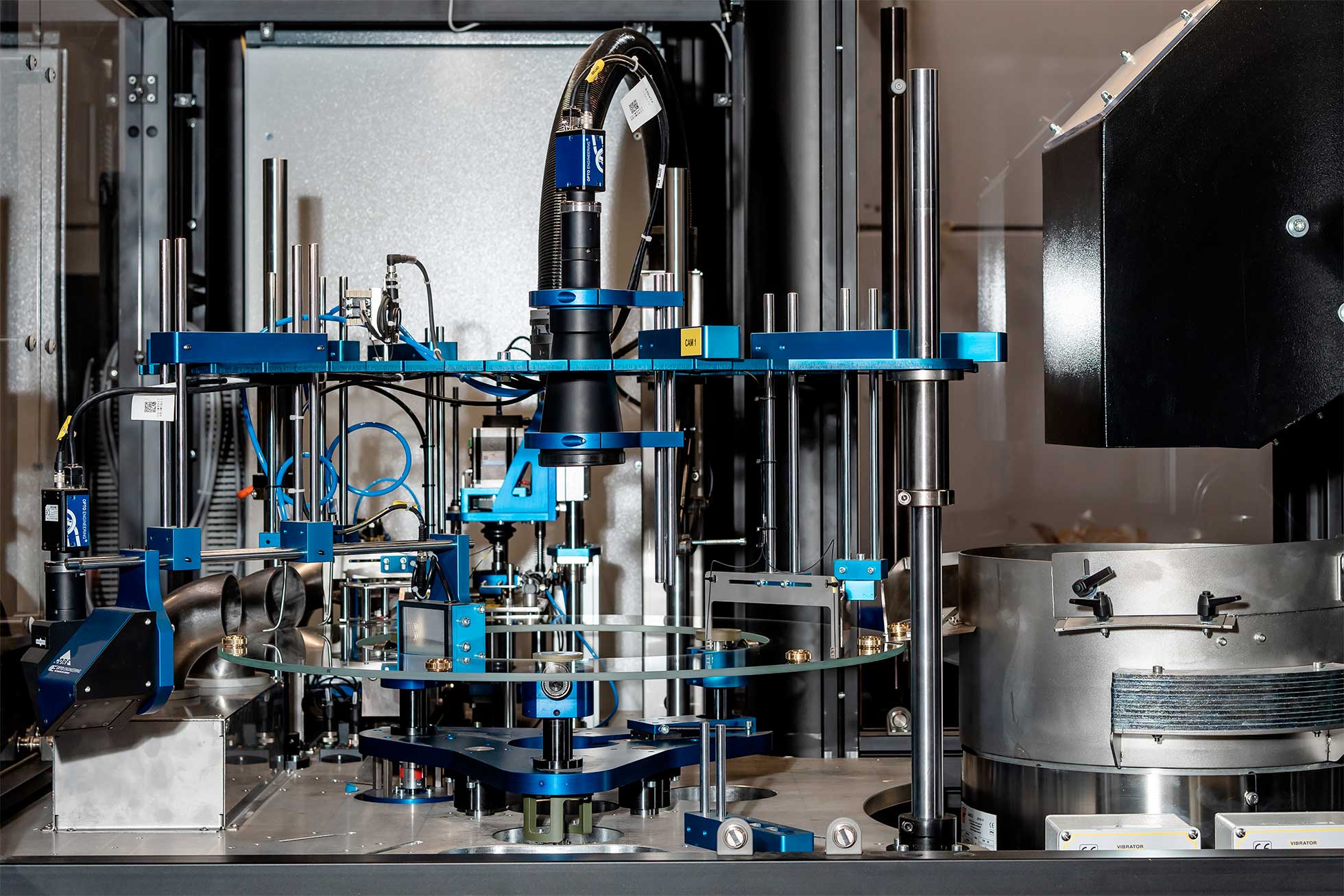

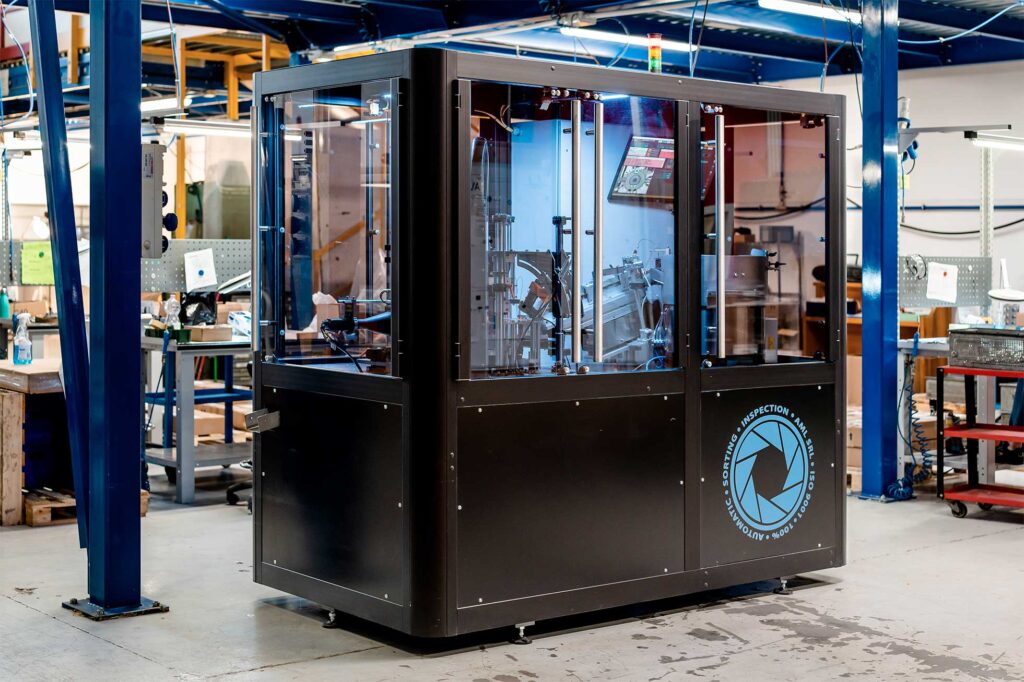

100% inspection and sorting machine with glass disk, designed to detect defects in components with flat surfaces. This solution allows optical inspection of the part through the glass disk using high-resolution cameras.

Glass disk machines include a circular vibratory feeder for loading parts onto the glass disk and multiple inspection stations positioned at various points around the disk (up to 12 stations).

Dimensions (lengths, heights, diameters, angles)

Form compliance

Incomplete parts

Presence of external and internal burrs/chips in the hole

hread control (height, pitch, partial presence, absence)

Presence of blind/through hole

Each glass disk machine starts with a standard configuration of 3 cameras, which can be modified according to the customer’s needs (up to 12 inspection stations).

The standard equipment includes:

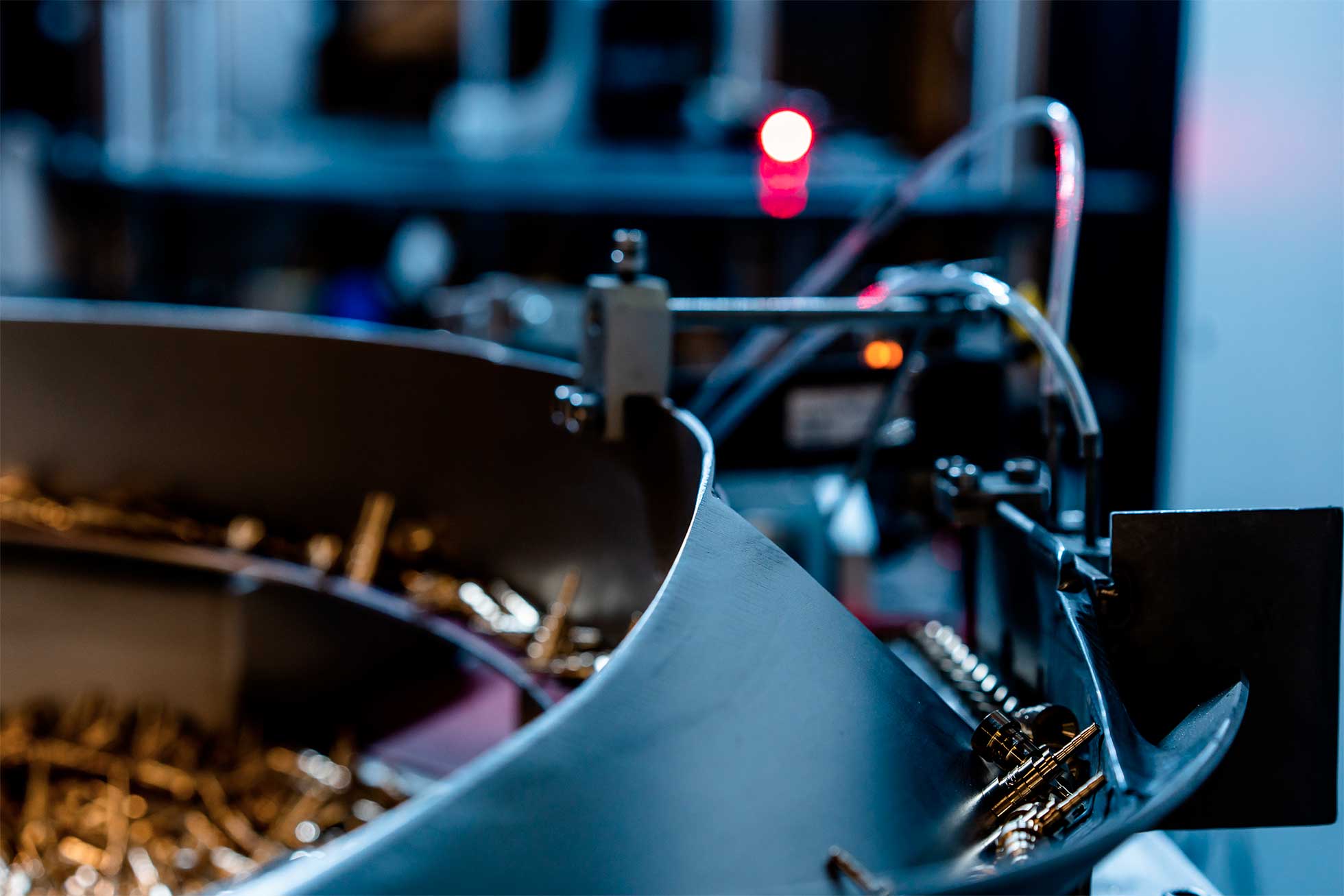

• Vibratory feeder for part loading

• Glass disk table

• 3 inspection stations

• ASEM 18.5″ Wide Screen touch panel with a clear and complete multilingual interface

for managing settings and custom recipes

• Unlimited number of recipes

• Sorting report with sorting statistics, measurements, and defect reports

• Data backup system

• Customizable inspection stations based on requirements (laser micrometer, go/no-go gauge, etc.)

AML machines are designed to adapt to different production needs. For this reason, they can be integrated with packaging and automatic loading systems, as well as various custom elements.

– Hopper for part loading

– Discharge magazine

– Camera integration

– Expansion of reject output channels